Biofuels startup LS9 just announced a breakthrough that could lower the cost of producing “drop‐in” hydrocarbon biofuels that are low‐carbon and compatible with the existing fuel distribution infrastructure.

In the article “Microbial Biosynthesis of Alkanes,” a team of LS9 scientists identified genes that, when expressed in E. coli, produce alkanes, the hydrocarbons that make up gasoline, diesel and jet fuel. This discovery is the first description of the genes responsible for alkane biosynthesis and the first example of a single step conversion of sugar to fuel‐grade alkanes by a "designer" microorganism, according to the company.

For decades scientists have attempted to identify the genes that allow certain natural organisms to directly convert biomass into alkanes. To solve this mystery, the LS9 team looked into the genomes of bacteria that produce alkanes in nature -- cyanobacteria, also known as blue-green algae. “We evaluated many cyanobacteria that made alkanes and identified one that was not capable of producing them. By comparing the genome sequences of the producing and non‐producing organisms, we were able to identify the responsible genes,” according to Andreas Schirmer, Associate Director of Metabolic Engineering at LS9.

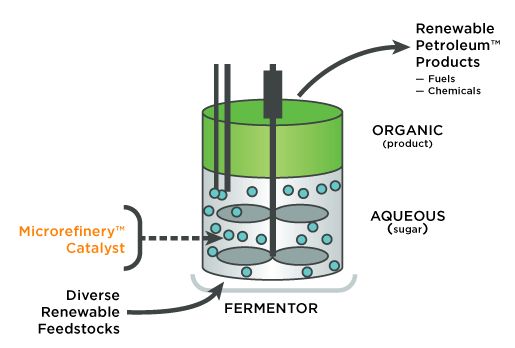

LS9 has focused on developing renewable petroleum products using a one‐step fermentation process that reduces cost and energy inputs. Proposed biological routes to hydrocarbon production are emerging but require costly and energy-intense chemical conversion technologies such as distillation or hydrogenation. LS9’s discovery could mean the direct conversion of renewable biomass into fuels and chemicals without the need for chemical conversion technologies.

“This is a one-step sugar‐to‐diesel process that does not require elevated temperatures, high pressures, toxic inorganic catalysts, hydrogen or complex unit operations,” said Steve del Cardayre, LS9's VP of R&D.

In addition to alkanes, LS9 is scaling up its production of a biodiesel product and a range of chemicals used in making industrial and consumer products.

The company claims that its synthetic fuels achieve 85 percent reduction of GHGs over a comparable gallon of petroleum-based diesel.

The company’s lead product is an alkane diesel of 8 to 20 carbons, which has already achieved ASTM approval. LS9 is also exploring the production of jet fuel. In the long term, the company seeks to produce low-volume, high-value specialty chemicals, traditionally made from petroleum. In May 2009, LS9 announced a strategic partnership with Proctor and Gamble to develop bio-chemicals for the consumer goods giant.

LS9 was founded in 2005 and has received more than $45 million in funding from Chevron Technology Ventures, Flagship Ventures, Khosla Ventures, and Lightspeed Venture Partners. The company recently purchased a demonstration-scale facility for $2 million in Okeechobee, FL.

In addition to LS9, many next-generation biofuel firms such as Algenol, Amyris, Aurora, Cobalt, Codexis, Gevo, Joule, Qteros, Sappire Energy, Solazyme, Synthetic Genomics, Terrabon, UOP, and Virent are looking to coax fuels from bacteria, algae or by other means. LS9, like Algenol, is looking for a direct mechanism from sugar to biodiesel or ethanol.

The enormous and looming challenge facing all of these companies, of which none have actually gotten far enough with the research process to confront, is the riddle of scaling up to the massive requirements of the liquid fuel market and getting the costs down to achieve pump parity. Without those two business achievements and the necessary capital, all of these firms remain noble science experiments.

More details on next generation biofuels from Greentech Media Research and the report: Third and Fourth Generation Biofuels: Technologies, Markets and Economics Through 2015.