Light emitting diode (LED) fluorescent tubes are all the rage in the lighting market these days. The technology promises to be more energy efficient, less environmentally harmful and more economical than traditional fluorescent tube lighting. Still, there is a lot of debate over whether they are ready for widespread commercial use.

We recently came across an instance in which this very debate was being discussed in a LinkedIn electrical construction group. It was a heated thread with two electrical contractors hashing out the pros and cons of using LED fluorescent tubes. To continue our series of articles on “green” construction, we thought we’d tackle the issue ourselves. So here we present our findings on LED fluorescent tubes.

What is a LED Fluorescent Tube? Actually, “LED fluorescent tube” is a misnomer. LED lights and fluorescent lights are completely different technologies. LEDs are very small bulbs illuminated by movement of electrons in a diode. Fluorescent bulbs use electrodes and a gas combination of argon and mercury to produce light. As such, the name “LED fluorescent tube” really refers to an LED tube that reminds us of traditional fluorescent tubes (such as the one that is likely overhead as you read this).

LED lights should also not be confused with compact fluorescent light (CFL) bulbs. CFLs use the same technology as fluorescent tubes to produce light, but on a smaller scale. They are a replacement for the incandescent bulbs commonly found in most home light fixtures. CFLs have garnered a lot of press because of their energy efficiency and environmental benefits (i.e., they are considered to be greener than traditional lights because they use less power).

An LED tube is made up of hundreds of individual LEDs. They come in a variety of sizes (2, 4 or 6 feet), different temperatures (i.e., different colors of light), and varying arrays of LEDs. They can be purchased with new fixtures, or used for retrofitting existing fixtures. However, they don’t require the ballasts that traditional fluorescents need, so those will need to be removed when replacing fluorescent bulbs with LED tubes.

When comparing LEDs to fluorescent tubes, here are four key specifications that should be reviewed:

- Lumens – This is the unit of measurement for strength of light. Look for tubes with 1500 lumens or more.

- Watts – This is a unit of measurement for power consumption. Four-foot LED tubes typically use 15 to 25 watts, while fluorescent tubes of this size use more than 30 watts.

- Lifespan – This is how long the bulb will last. It’s measured in hours. 50,000 hours is common for LED tubes.

- Color temperature – The temperature of the light is the color of the light. It is measured in units of absolute temperature, or Kelvin (K). 3000K is considered warm (redder), 4100K is considered neutral, and 5800 K is cool (bluer).

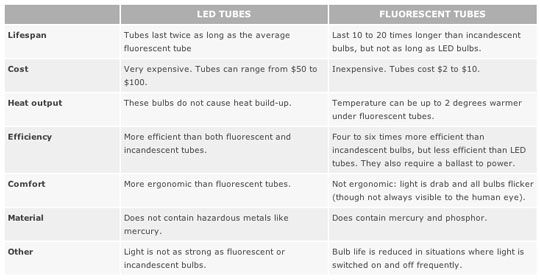

Pros and Cons of LED and Fluorescent Tubes. To give recognition where it’s due, fluorescent tubes are a great invention. They have been lighting most of America ever since GE brought them to market back in 1938. They are four to six times more energy efficient than incandescent bulbs and are said to last 10 to 20 times longer. Of course, they come with their own set of disadvantages, as well.

Fluorescent tubes contain mercury and phosphor, which present a number of health and environmental risks. The lights require a ballast, which adds to the cost of the lamp and can cause a buzzing noise. Finally, they frequently flicker, and the light is often drab.

On the other hand, LED bulbs last longer than fluorescents, and they don’t contain harmful ingredients like mercury. Perhaps most signficantly, LEDs use much less power than fluorescent lamps -- and there are many other benefits, as well.

Still, LEDs aren’t perfect. The tubes are generally not as bright and can cost more up front. And unfortunately, cost will likely be the number-one driver of greater adoption. So let’s compare the costs of each type of bulb:

Costs of LED Tubes vs Fluorescent Tubes. The debate over LED vs fluorescent tubes always teeters when it comes to the cost argument. When comparing the upfront cost of one LED tube to one fluorescent tube, fluorescent wins, hands-down. However, when you consider volume discounts and the longer lifespan of LEDs, the scale leans the opposite direction. Let’s compare the costs of each taking these factors into consideration.

This table compares the first-year cost of a single commercial-grade (i.e., UL and CE compliant), four-foot T8 LED tube to a four-foot T8 fluorescent tube. To measure kilowatts per year, we assumed the lights would be on for 12 hours a day, 255 days a year. We used an average energy rating of 20 watts per hour for LEDs and 32 for fluorescents. To calculate energy cost, we used an average cost per kilowatt of $0.11.

Clearly, fluorescents are less expensive in the first year. However, when you account for product longevity, LED tubes are the winner. LED tubes last an average of 50,000 hours (roughly 16 years) while fluorescent T8 tubes last an average of 25,000 (roughly 8 years). To determine this, we looked at every fluorescent T8 tube that Sylvania offers (nearly 150) and calculated average lifespan. To be precise, it was 24,787.67 hours.

In this next table, we compare the 16-year cost (the lifespan of an LED tube) of 40 LED tubes compared to 40 fluorescent tubes. In this example, the number 40 is somewhat arbitrary. We have 20 2′ x 4′ fixtures in our office, so we chose 40 bulbs as our basis of comparison. Keep in mind, fluorescent fixtures require ballasts, so we’ll need to tack on an additional $400 to fluorescent tubes (20 ballasts at $20).

Using prices from our previous table, in the first year it will cost $3,069 for the energy and initial purchase of 40 LED tubes. The fluorescent tubes would cost $1,071. Every year thereafter, the energy costs of LED tubes will be $269, and $431 for the fluorescents. In the eighth year, the fluorescent bulbs will need to be replaced at a cost of $240.

You’ll notice the numbers in our table look a little different. That’s because we’ve included an annual energy inflation rate of 5%. We also used a 2.5% inflation rate to calculate the cost of the replacement fluorescent bulbs in the eighth year. Finally, we used a 6% discount rate to determine the net present value (NPV).

As our analysis reveals, the 16-year cost for 40 LED tubes is $6,431, while the cost for fluorescent tubes is $6,846. This is 6% in savings over the life of the tubes. Keep in mind, this is only 40 tubes. Building owners with more light fixtures will realize more savings, as the volume discount will be greater and energy costs will be lower. So, over the lifespan of the product, LED tubes are more cost effective than fluorescent tubes.

A Bright Future for LED Tubes. The cost of manufacturing LEDs is dropping. Researchers at Purdue University have developed a way to create LEDs using inexpensive, metal-coated silicon wafers instead of expensive sapphire-based bulbs. This discovery has the potential to bring the cost down to levels competitive with fluorescent tubes. You can stay up to date on news of this development over at the Eartheasy blog.

In the meantime, there’s no reason electrical contractors shouldn’t promote LED tubes. LED tubes can help building owners achieve eligibility for government and utility company incentives. They help companies capture the desirable -- and highly marketable -- green cachet. They provide greater energy cost savings than fluorescents. And finally, they are simply better for the Earth. They are the future of commercial lighting.

This article originally published on Software Advice at: Are LED Fluorescent Tubes Ready for Prime Time?