Algae biofuels are often considered one of those technologies --- like hydrogen fuel cells --- that are always "ten years away." Well, one company says it might have just cracked the code and could be supplying lots of algae jet fuel and diesel in the coming years.

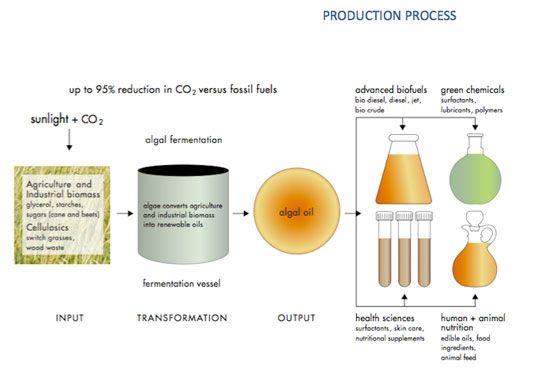

In the race for algae biofuel commercialization, people usually compare open ponds with photobioreactors. Solazyme, however, bypasses photosynthesis (and conventional wisdom) by growing algae in dark fermentation tanks.

Grow algae in dark tanks?! Isn't that like putting solar panels on the dark side of the moon?!

Not really.

Most algae strains are photosynthetic and utilize the sun to transform C02 into useable energy. Among the most productive and fastest growing organisms on the planet, algae can double in size daily and account for approximately 60% of the oxygen production on Earth. Some strains comprise up to 50% of their body weight as a lipid (oil).

Excitement for algae in recent years has largely been driven by their superior yields. For example, corn ethanol --- the dominant feedstock for ethanol in the United States --- yields the equivalence of 270 gallons of gasoline per acre per year. Algae's yields are somewhere between 1500-8000 gallons per acre per year --- depending upon the strain's genetics, growth method, access to key nutrients, and location.

In addition to superior yields, interest in algae has been driven by the fact that algae can thrive in wastewater, greywater, or salt water, can grow on marginal or desert land, consumes C02 as a feedstock, and could possible be used for wastewater remediation.

Algae also completely bypasses the "food vs. fuel" issues, Indirect Land Use Changes (see Inconvenient Truth: Biofuels Have a Carbon Footprint), downstream petroleum infrastructure incompatabilities, fresh water limitations, questionable energy and GHG emission balances, and all the other reasons why corn ethanol and most other First Generation biofuels are unsuitable candidates to ever wean us off our crack-like addiction to petroleum.

Although many of us believe in algae's long-term prospects, its short-term viability has been limited by unfavorable economics --- calling many to conclude that algae biofuels are all sizzle and little steak.

Although open ponds and photo-bioreactors (PBRs) have very different cap-ex and op-ex cost structures, both systems are defined by an algae lifecycle that goes something like this:

An algae strain must identified and/or optimized for maximum growth and potential to ward of invasive species. The correct location must be found and as the algae grow, they need a constant supply of nutrients, C02, heat, and light which requires the consistent movement of water. Once the algae grows to a sufficient mass, it must be harvested, dewatered, and dried before extraction of the oil can commence. These steps are energy and capital intensive.

Once the oil is extracted, it is relatively simple to upgrade the fuel into jet fuel or diesel using traditional refinery techniques but still costs an additional $0.25-$0.40/gal. Taken together, algae grown via open ponds and PBRs are estimated to currently cost $8-$30/gal. (see Biofuels 2010: Spotting the Next Wave).

While some companies like Synthetic Genomics are attempting to genetically modify algae strains to secrete the lipids as they grow (known as "wet extraction") and others like OriginOil have developed a technology platform that reduces the aforementioned steps using fancy centrifuges and electromagnetic pulses, there are significant questions about the ability of these systems to scale.

Which brings us to Solazyme.

By growing their algae in dark vessels, the company does not incur the energy costs of providing the algae artificial light. Heterotrophic fermentation requires a fraction of the amount of water as a PBR or open pond. These strains of algae do not require C02 --- which is widely accepted among algae experts as the one of the two largest logistical obstacle for photosynthetic algae commercialization. The other is removing the water, which isn't an issue when growing it in dark vessels.

Solazyme will basically feed their algae sugar until they are large, round, and ready to explode with oil --- kind of like Violet Beauregarde in Charlie in the Chocolate Factory. The company has not disclosed its extraction method but claims that it will only cost several cents per gallon.

While Solazyme will need copious amounts of sugar to feed the algae which could catapult the company into the "food vs. fuel" debate --- Solazyme has a supply agreement with second generation pioneer BlueFire Energy to obtain sugars derived from cellulosic (i.e. non-food) sources.

Given that the company is using fermentation --- a well established technology used to make beer and ethanol--- creating and scaling facilities will not be as big of an impediment as the 150 or so other approaches that vacilliate from flooding the Arizona desert with seawater to extracting algae oil from live fish (see Live Fuels).

Still skeptical?

Solazyme has a few other tricks up its sleeve.

It is among the most well capitalized advanced biofuel companies raking in more than $100M since inception. It recently received an additional $22M in DOE financing for its demonstration-scale facility to prove it is ready to scale to a commercial plant.

In the coming months, Solazyme will deliver 20,000 gallons of algae jet fuel to the U.S. Navy. While 20,000 gallons will hardly scare the Saudis into turning Ghawar into an algae R&D lab, this number needs to be placed in the context of the fact that few --- if any --- other algae company has ever produced more than a few hundred gallons in their entire company's operating history.

Additionally, Solazyme is already selling nutraceuticals, powered oils, and oleochemicals for $3-$10/lb. The company anticipates that its total levelized costs will come down to $1.50-$2.00/gal by 2012.

We have even heard grumblings that the company is in the early stages of engineering on a 100 MGY commercial facility that would open in 2013.

Maybe algae isn't ten years away afterall...