In order to stay competitive with crystalline silicon (c-Si), thin-film solar manufacturers such as the leader in that technology, First Solar (Nasdaq: FSLR), have to continue to keep their eye on costs but must also raise efficiency.

First Solar has had a modest but consistent ramp in conversion efficiency of roughly 0.1 percentage point per quarter. It doesn't sound like a lot, but it starts to add up over time. The average line conversion efficiency for First Solar's modules was 12.4 percent in the first quarter of this year.

First Solar set a new world record for CdTe PV module efficiency with a 14.4 percent total area efficiency in January. That mark came after First Solar hit a CdTe solar cell efficiency of 17.3 percent. Both records were set at the firm's Perrysburg, Ohio factory.

So there's headroom and the potential to really give c-Si a run for the money on efficiency. But First Solar has to keep hammering on the potential of the CdTe materials system, as well as the other pieces of the module stack, such as the Transparent Conductive Oxide (TCO). As a testament to First Solar's intense need for improving performance, the firm has reached out and formed a partnership with Intermolecular (Nasdaq:IMI).

Intermolecular uses a combinatorial experiment technology that comes out of biotech firm Symx. First Solar looks to Intermolecular's High Productivity Combinatorial (HPC) platform to help develop more advanced, CdTe-based PV manufacturing processes. Intermolecular acts as an R&D accelerator, and in turn, Intermolecular typically gets a royalty from products sold that were developed with its technology -- although First Solar did not divulge the exact nature of the partnership.

We spoke with Raffi Garabedian, First Solar's CTO about the partnership. Garabedian said, "The device we make is a semiconductor junction and very similar to a CMOS device -- and you can imagine that Intermolecular's process expertise could be turned to PV."

Higher efficiencies will reduce area-related costs and eliminate the balance of system penalty. According to a GTM Research model, CdTe must sell for $0.12 to $0.16 per watt less just to compensate for the BoS penalty.

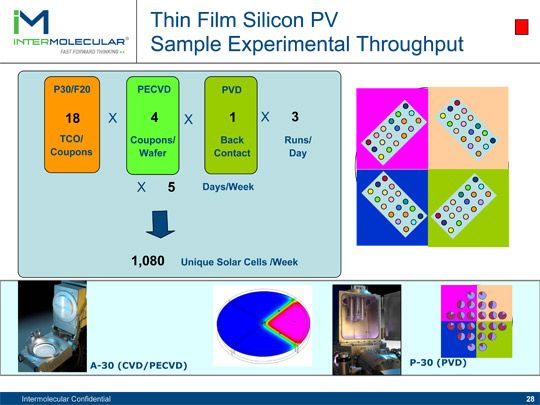

Intermolecular's claim to fame is its ability to do many experiments on a single wafer -- up to 72 experiments per cycle. These are essentially miniaturized and site-isolated experiments. As an example, a wafer can be run with 18 different silicon wafer texturing processes, each with four different passivation techniques.

In a project that would take another company months to complete and likely tax its analytical capabilities, Intermolecular can have a throughput of hundreds of uniquely characterized solar cells per week. Intermolecular has the flexibility to change gases, targets, chemistries and integration schemes. This is combined with automated probing and an "Informatics" software system that in many ways is similar to the techniques employed in biotech.

Intermolecular has worked on projects aimed at improving alkaline texturing of monocrystalline silicon wafers and developing a more durable, lower-cost antireflective coating for PV glass. Another project was a development program focused on making high-efficiency CIGS more readily manufacturable. The company is also considering programs targeting optimized transparent conductors and efficiency enhancements for earth-abundant PV materials like CZTS.

Garabedian added, "Cadmium telluride is still in its infancy, and First Solar has just scratched the surface. We've been focused on growth in the last few years -- we're now entering a time to really move the needle to accelerate performance."

Craig Hunter, Sr. VP of Global Sales and Marketing, echoed Garabedian, saying, "What we exist to do here is accelerate learning curves. Look at the headroom on the CdTe device -- there is tremendous opportunity to improve. CdTe is still an immature technology -- like most of PV."